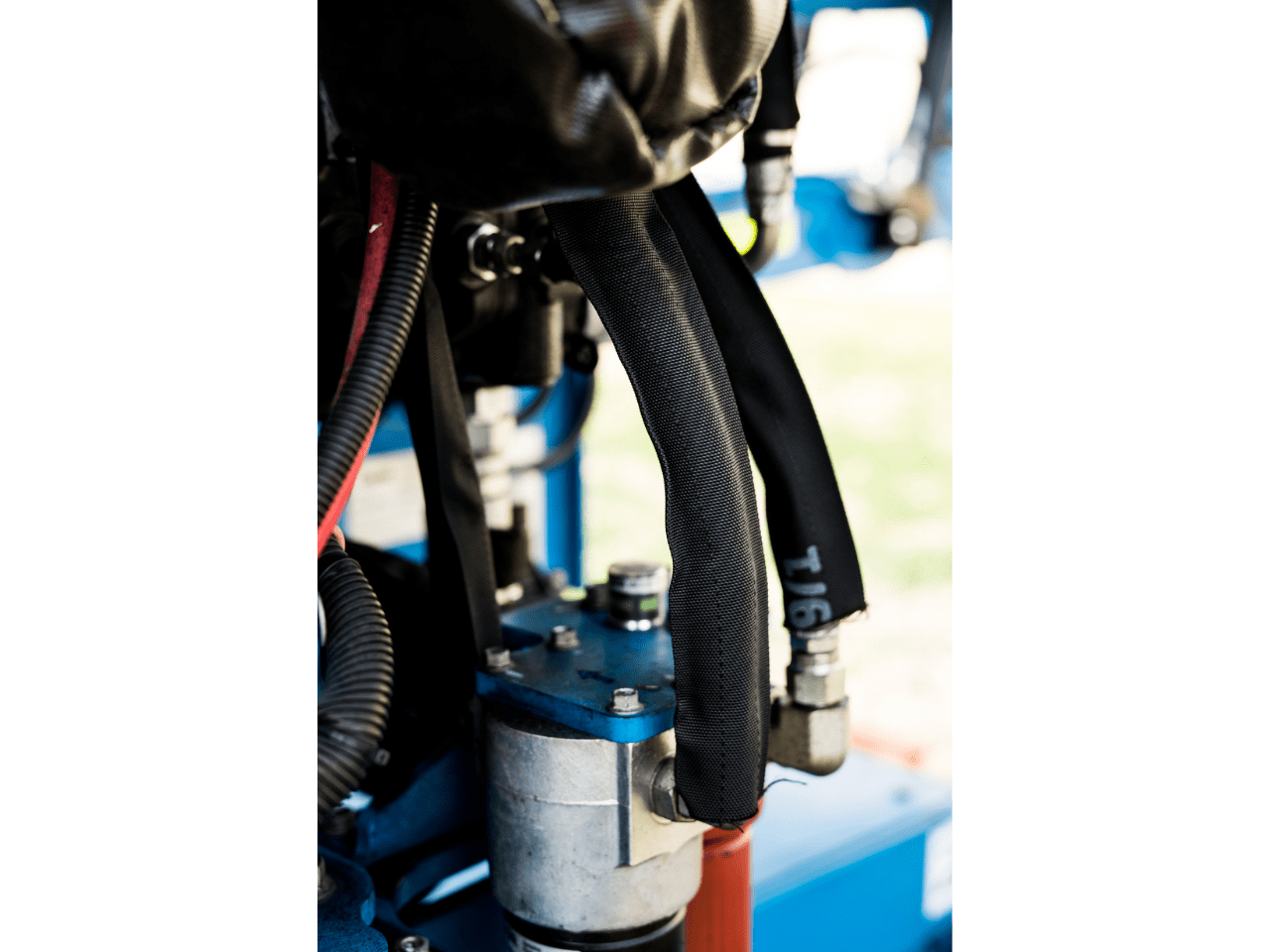

Hydraulic Hose Burst Protection Sleeve

Couldn't load pickup availability

Prevent Injuries. Avoid Downtime. Comply with Regulations.

Hydraulic Hose Burst Protection Sleeve is designed to provide critical safety in high-pressure hydraulic systems by containing fluid in the event of a hose failure. This protective sleeve reduces the risk of fluid injection injuries and minimizes hazards to personnel and equipment.

A burst or pinhole leak in a hydraulic line can result in serious injuries—including oil injection that may require surgical intervention or even lead to amputation. Additionally, hydraulic fluid sprayed onto hot machinery can cause fires. To address these risks, the Department of Primary Industries mandates burst protection for hydraulic hoses in areas where personnel or the environment could be at risk.

Our burst sleeves are available in a range of sizes and configurations to suit various hose types. They are simple to install and offer durable, reliable protection for your hydraulic systems.

Minimum order of 1 roll (50m).

Key Benefits:

-

Protects against fluid injection injuries

-

Reduces fire hazards caused by oil spray

-

Complies with industry safety regulations

-

Easy to install and maintain

Technical Specifications:

-

Certification: MSHA-approved

-

Material: High-strength nylon yarn

-

Temperature Range: -50°C to 150°C

- Sizes: Available in several diameters, from 17mm to 110mm.

-

Length: Supplied in minimum of 1 roll (50m roll).

-

Chemical Resistance: Resistant to most oils, solvents, acids, and alkalis

-

Low Dirt Adhesion: Helps maintain performance and cleanliness

-

Standards: Meets EN ISO 3457 safety requirements

Common Applications:

-

Industrial Equipment

-

Construction Machinery

-

Agricultural Machinery

-

Marine Applications

-

Mining Operations

Frequently Asked Questions

What is hydraulic hose burst sleeve protection?

A hydraulic hose burst sleeve is a durable outer covering that wraps around hydraulic hoses to contain leaks or bursts. It’s typically made of woven nylon or polyester and is designed to direct escaping fluid safely along the length of the hose.

How long do hydraulic hoses last?

Lifespan depends on usage and maintenance. In well-maintained systems, hoses can last over two years. In harsher environments, the lifespan may be reduced to 1–2 years.

Why do hydraulic hoses burst?

Common causes include abrasion, kinking, crushing, excessive pressure, or improper installation.

What are the risks of a hydraulic hose bursting?

A burst hose can lead to severe injuries from high-pressure oil injection and fire hazards if oil contacts hot surfaces.

How does the burst sleeve work?

The sleeve disperses the energy of a fluid burst, redirecting the oil down the inside of the woven sleeve and away from people or machinery.

What is the sleeve made of?

Our burst protection sleeves are constructed from premium-grade nylon yarn for strength, flexibility, and long-term durability.